This factory shows you all procedures of our custom handmade knives. Free forging technique, which is inherited by swordsmith, is adapted in this process. From blade tip to handle end, it is carefully and thoughtfully finished by our craftsmen and women.

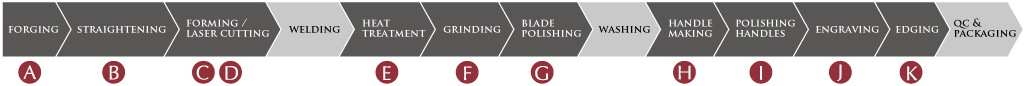

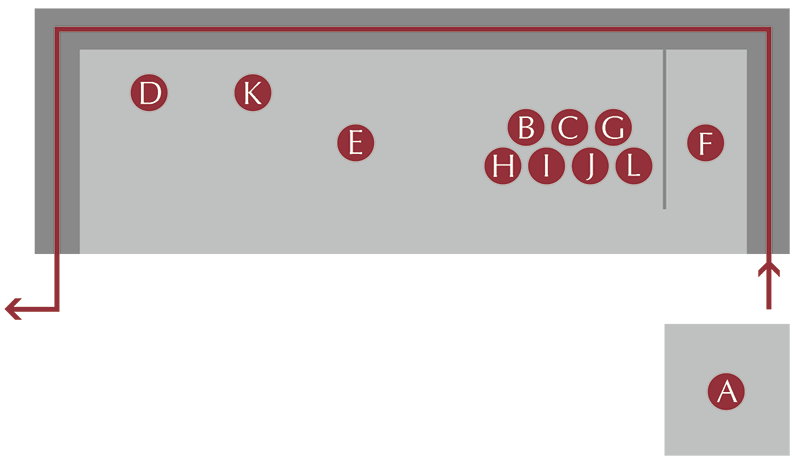

Facility Guide

Map and process.

Click on process or alphabet to see pictures.

Forging

Forging

Hammer-forge heated steel and form basic knife shape.

Forming

Forming

Fix distortion from forging, grind and shape up blade.

Heat treatment

Heat treatment

Giving steel both hardness and flexibility by heating up with high temperature.

Grinding

Grinding

Grind blade to form knife shape.

Handle making

Handle making

Processes sheet material into knife handle.

Polishing Handles

Polishing Handles

Smoothly polish handle and make it into the shape that comfortably fits in your hand.

Engraving

Engraving

With chisel and hammer, hand-engrave the name one by one.

Edging

Edging

Sharpen the edge from coarse, medium, fine, and extra fine grind.

Facility Guide

| A | Forging |

|---|---|

| C | Forming |

| E | Heat Treatment |

| F | Grinding |

| H | Handle Making |

| I | Polishing Handles |

| J | Engraving |

| K | Edging |

Forging

Forging

Hammer-forge heated steel and form basic knife shape.

Forming

Forming

Fix distortion from forging, grind and shape up blade.

Heat treatment

Heat treatment

Giving steel both hardness and flexibility by heating up with high temperature.

Grinding

Grinding

Grind blade to form knife shape.

Handle making

Handle making

Processes sheet material into knife handle.

Polishing Handles

Polishing Handles

Smoothly polish handle and make it into the shape that comfortably fits in your hand.

Engraving

Engraving

With chisel and hammer, hand-engrave the name one by one.

Edging

Edging

Sharpen the edge from coarse, medium, fine, and extra fine grind.